Industrial

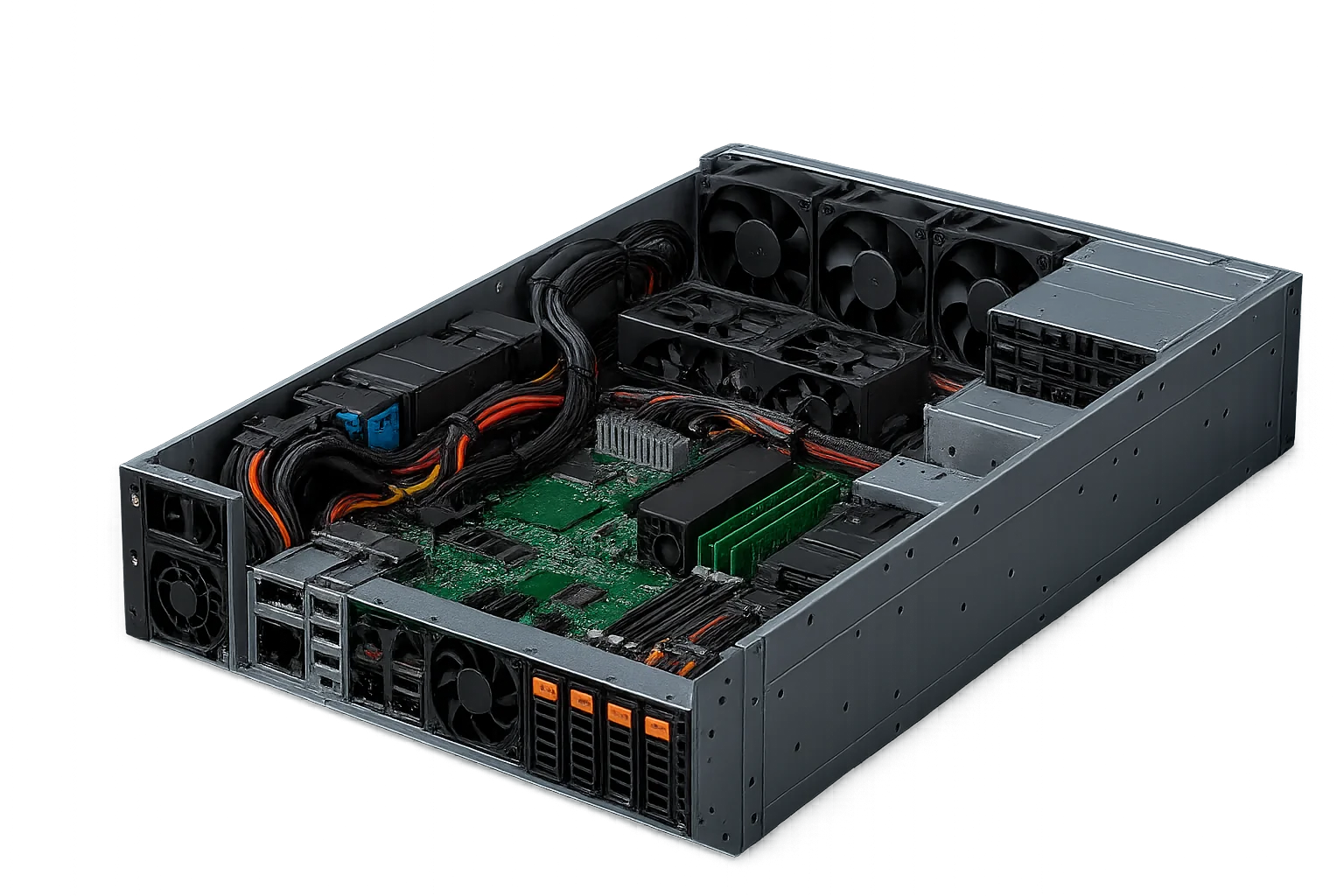

Industrial controller

Panel PCs with PCBAs, fans, heaters, and harnessing; hi-pot and burn-in for every lot.

Hi-potHarnessBurn-in

SYSTEM INTEGRATION

Dedicated integration cells manage PCBA install, harness build, firmware load, functional/hi-pot test, torque logging, and packaging so every finished unit ships with MES-backed traceability.

Each enclosure ships with torque, test, and serialization data tied to its traveler.

Rack, desktop, and IP54–IP65 housings.

Cut/strip/crimp, continuity, and label on every harness.

ICT/FCT/hi-pot with firmware revision capture per unit.

BOX-BUILD COVERAGE

Mechanical integration, wiring, power checks, firmware load, final test, and packaging handled by one accountable crew.

Mechanical integration

Mount PCBAs, displays, fans, and hardware with calibrated torque and gap checks.

Harness fabrication

Cut/strip/crimp AWG 28–8, labeling, continuity/hi-pot verification, and routing.

Firmware & test

Program via JTAG/SWD/USB, run functional, ICT/FCT, boundary-scan, and hi-pot with logged results.

Packaging & logistics

ESD/foam/retail kitting, accessories, barcodes, ASN/EDI, and D2C fulfillment.

WORKFLOW

From incoming PCBA to serialized, tested, packed systems.

Plan & stage

Review BOM, wiring, torque specs, firmware, and test limits; stage fixtures and jigs.

PCBA install

Install boards, cooling, displays, and hardware with calibrated torque and gap checks.

Harness & routing

Build, label, and route harnesses with strain relief and continuity/hi-pot checks.

Firmware & test

Load firmware and run ICT/FCT, boundary-scan, and hi-pot with logged pass/fail and waveforms.

Pack-out

Accessory kit, manuals, labels, carton/pallet prep, and ASN/EDI for outbound lanes.

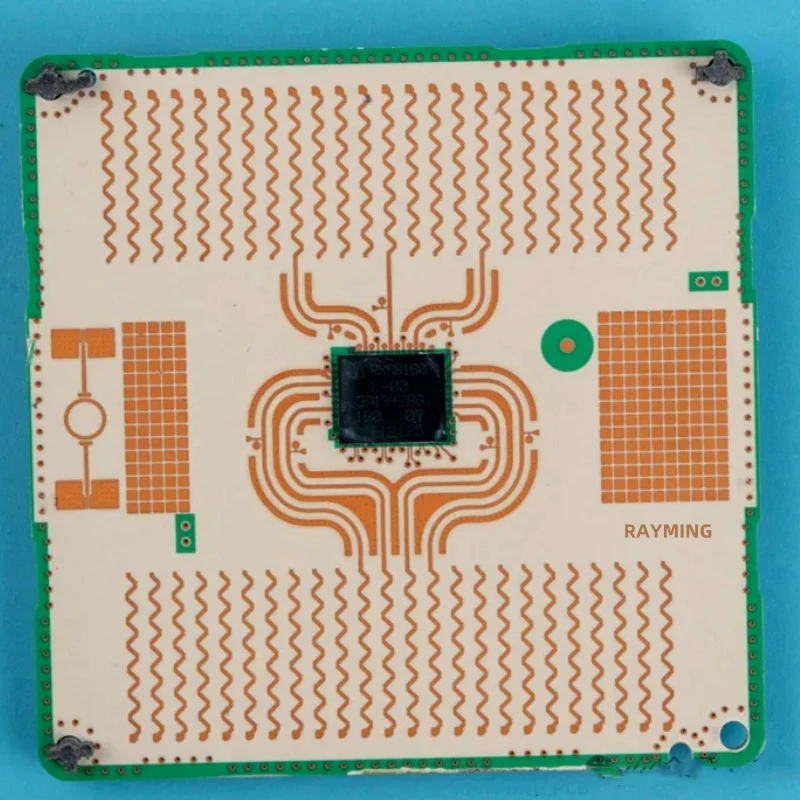

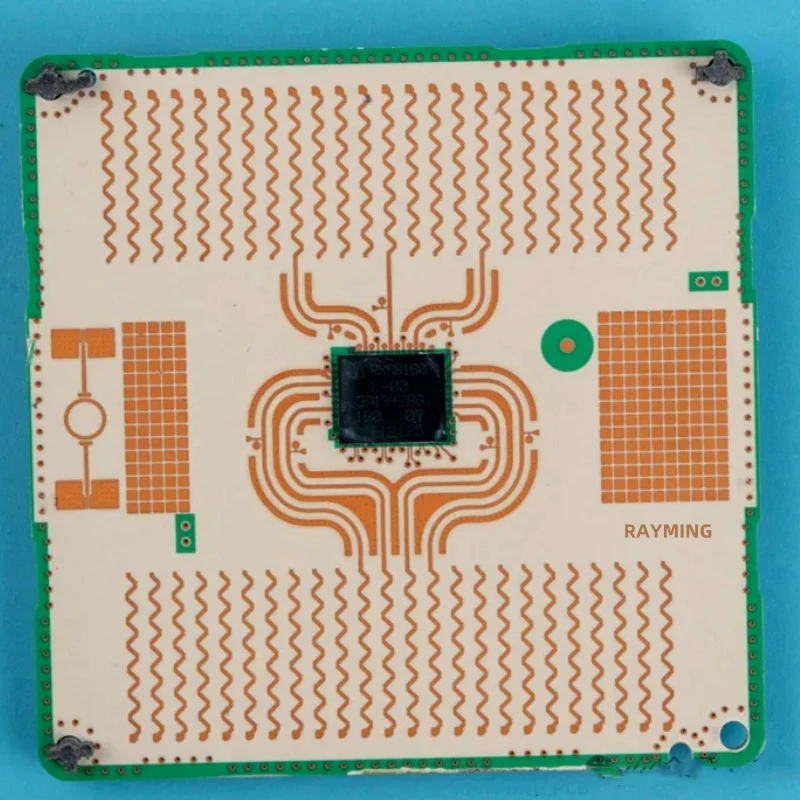

PORTFOLIO

Integration examples spanning industrial, medical, and consumer systems.

CAPABILITIES

Cells, tools, and data capture built for reliable electromechanical builds.

ESD-controlled cells with MSD handling, torque calibration, and dedicated packaging zones.

QUALITY

Inspection, torque, and test aligned to integration and regulatory needs.

Digital drivers with calibration logs, gap checks, and visual inspections.

Continuity and hi-pot on every harness before install plus label verification.

ICT/FCT, boundary-scan, firmware revision capture, and hi-pot with MES serialization.

Rugged assemblies with hi-pot, thermal management, and conformal coat.

ISO 13485 flows with UDI, cleanliness controls, and documentation rooms.

RF calibration, firmware load, and retail/D2C pack-out for gateways and hubs.

Accessory kitting, manuals, labeling, and palletization for direct ship.

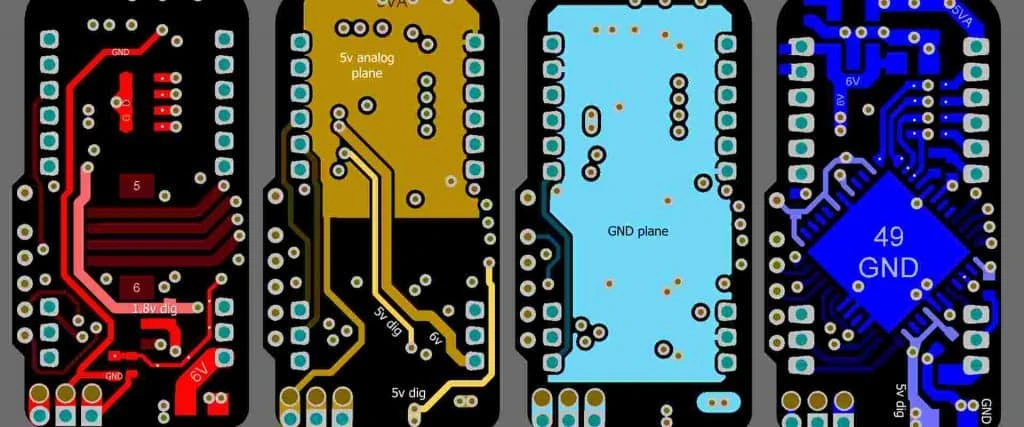

Everything you need to know about HDI PCB technology

Upload your integration package to receive a complete plan for build, test, and logistics.