Design & NPI

Engineering support before the first build.

- •PCB Design Support — SCH, PCB layout, and 3D assembly guidance.

- •NPI — cross-team kickoff and readiness planning.

About

From PCB design support and fabrication to component sourcing, SMT/DIP assembly, testing, and logistics—managed by one team.

Guangdong APTPCB Electronic Technology Co., Ltd.

Key milestones in the growth of APTPCB’s PCB and PCBA operations.

A cross-functional structure to keep engineering, procurement, manufacturing, and quality aligned.

What you can gain from APTPCB—delivered end-to-end with a single point of accountability.

Coverage from design support and fabrication to sourcing and assembly.

Engineering support before the first build.

Board build coverage across common technologies.

Turnkey or consigned, aligned to your BOM and build plan.

Quality checkpoints and documentation for shipment.

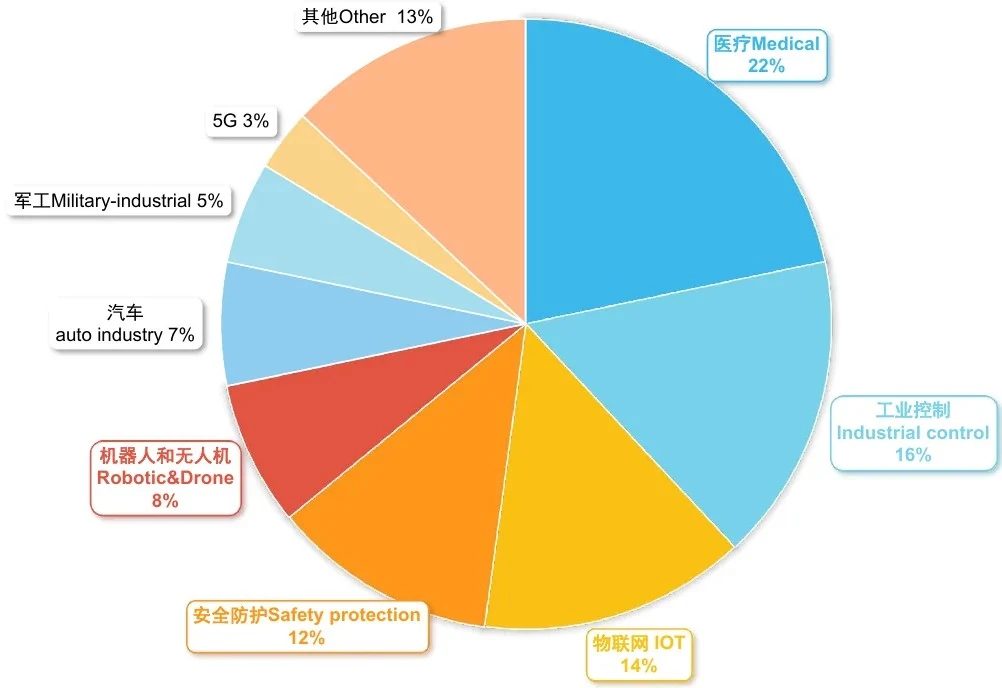

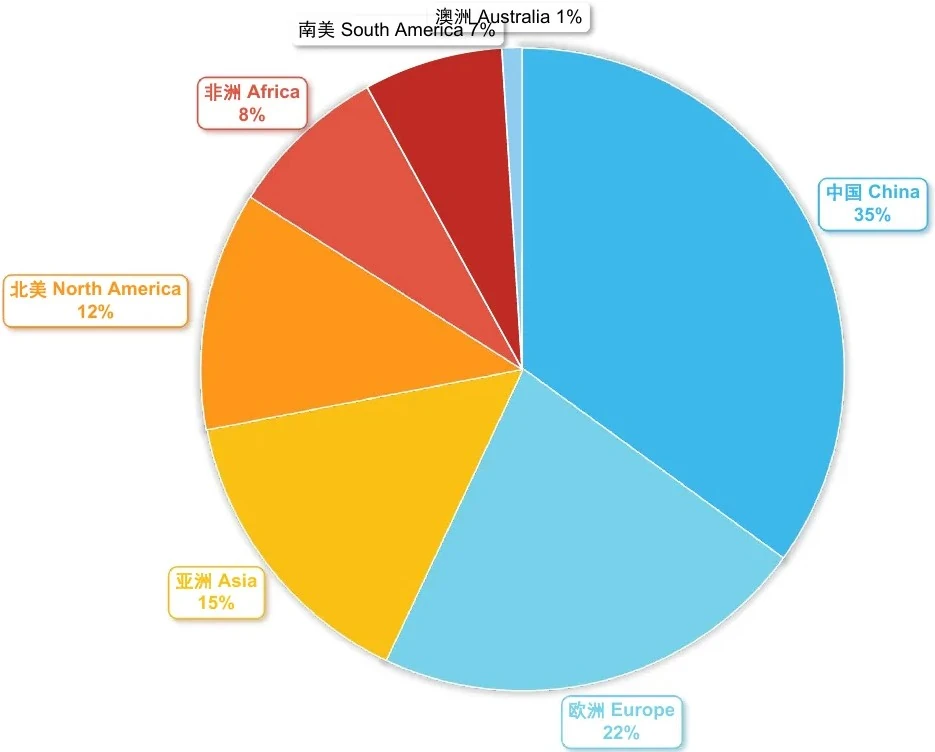

A quick look at the industries we support and where our customers are located.

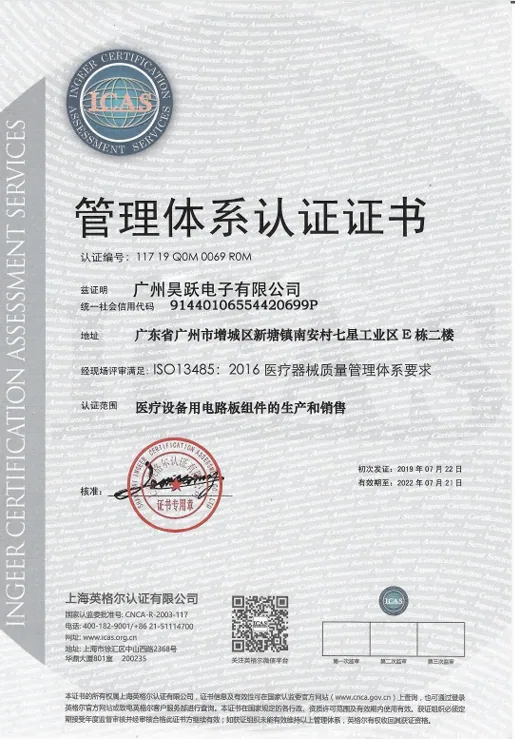

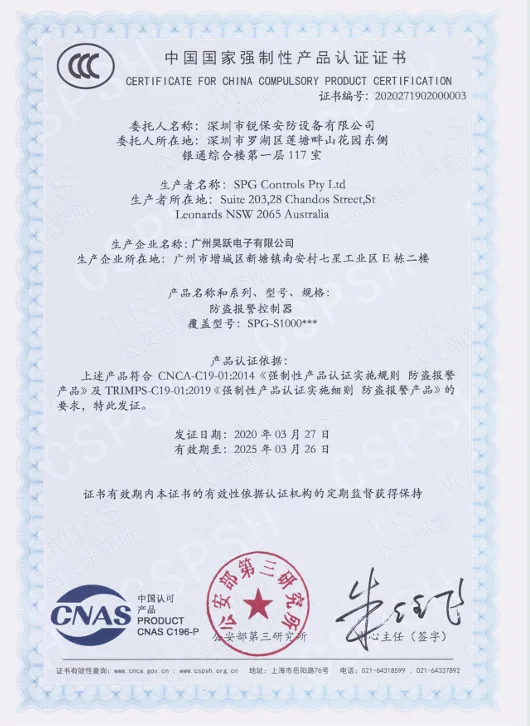

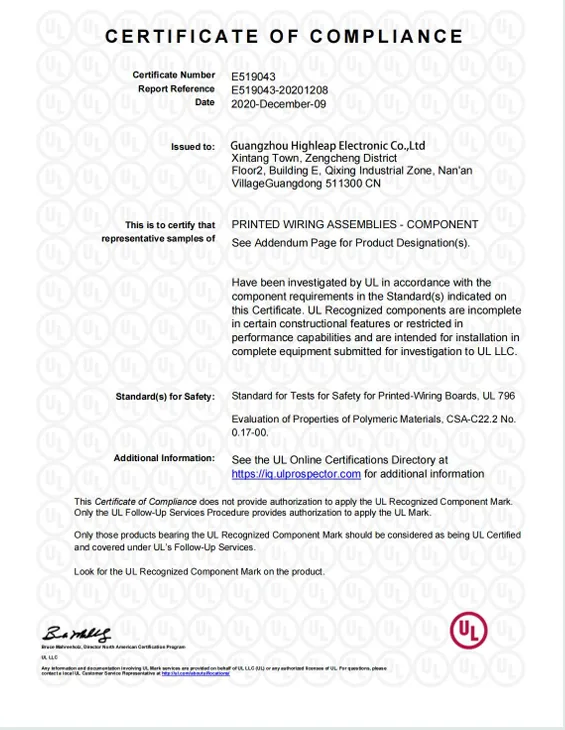

Programs supported across medical, industrial, IoT, energy, robotics, and more.

Global delivery coverage aligned with international customers.

Experience, quality management, and response speed built into everyday execution.

PCB fabrication and PCBA assembly capacity, teams, and coverage at a glance.

Multi-product fabrication coverage for rigid, flex, rigid-flex, HDI, and specialty builds.

SMT + DIP assembly with inspection and functional test coverage for turnkey builds.

A snapshot of key production and inspection equipment supporting consistent builds.

Direct imaging for fine-line accuracy and repeatability.

Stable copper plating and through-hole reliability controls.

High-precision drilling support for HDI and complex stack-ups.

Paste volume and alignment checks to improve first-pass yield.

Placement coverage down to 01005 capability (per presentation).

Inspection for hidden joints and dense BGA packages.

Hardware, schematic, PCB layout, and 3D assembly support.

Hardware design and schematic (SCH) support.

PCB layout support with manufacturability checkpoints.

3D assembly support for fit checks and integration planning.

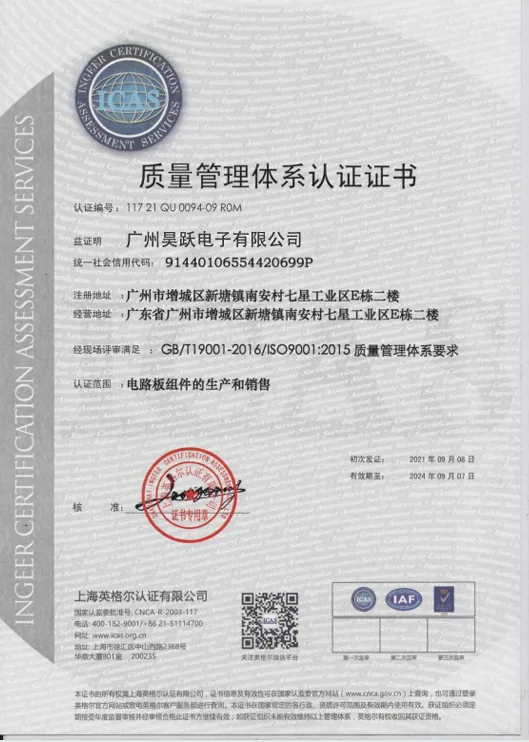

Controls spanning DFM, sourcing, fabrication, assembly, inspection, and functional test.

We strive to be your best partner in Electronics Manufacturing Services (EMS). PCB Design · PCB Fabrication · Components · Finished Products Assembly · SMT · DIP.

Contact us today to discuss your PCB requirements and get a customized quote for your project.