Materials

Rogers High-Frequency PCB Manufacturing Services

At APTPCB, we transform high-performance Rogers laminates into precisely manufactured printed circuit boards. We are not a material distributor; we are a specialized PCB manufacturing and assembly factory. We partner directly with Rogers Corporation and authorized channels to source genuine materials, ensuring your high-frequency designs—from 5G antennas to aerospace sensors—perform exactly as simulated.

Get an Instant Quote

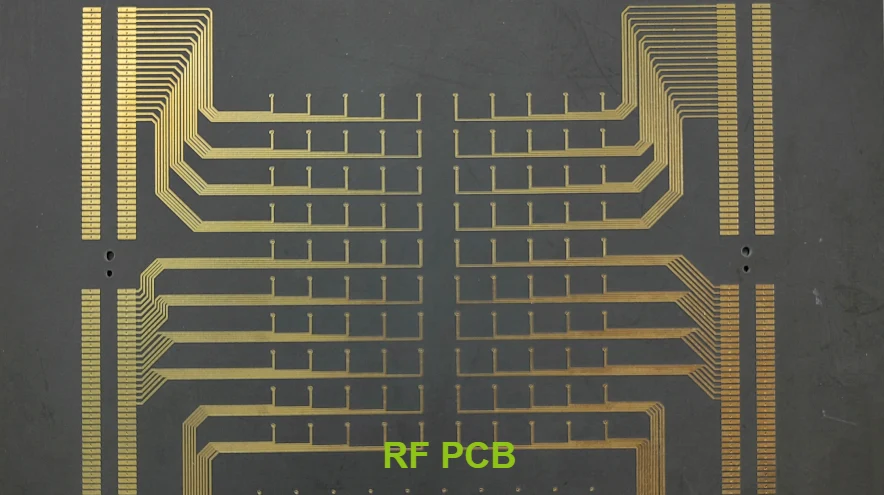

Turnkey Fabrication & Assembly for RF/Microwave Circuits

Looking for a specific Rogers laminate?

Don't worry about material sourcing. Share your Gerber files and Target Material Model, and our engineering team will handle the supply chain and fabrication analysis.

Comprehensive Rogers Material Series & Models Support

We have mature processing capabilities for the full spectrum of Rogers materials. If your design specifies any model listed below, we can manufacture it.

| Series | Key traits | Representative models |

|---|---|---|

| RO4000 Series (Hydrocarbon Ceramic) | Easy processing compatible with FR-4 processes; low loss; strong price-performance ratio. | RO4350B; RO4003C; RO4835 / RO4835T; RO4450F / RO4450T; RO4360G2; RO4533 / RO4534 / RO4535; RO4725JXR / RO4730JXR / RO4730G3; RO4000 LoPro |

| RO3000 Series (PTFE with Ceramic Filler) | Consistent dielectric constant over temperature; benchmark for 77 GHz automotive radar. | RO3003 / RO3003G2; RO3006; RO3010; RO3035; RO3203 / RO3206 / RO3210 |

| RT/duroid Series (PTFE Composites) | Lowest possible electrical loss; trusted by aerospace and defense industries. | RT/duroid 5880 / 5880LZ; RT/duroid 6002; RT/duroid 6006 / 6010LM; RT/duroid 6202 / 6202PR; RT/duroid 5870 |

| TMM Series (Thermoset Microwave Materials) | Dk stability of ceramic with thermoset processing ease; wire-bondable; copper-matched CTE for PTH reliability. | TMM 3; TMM 4; TMM 6; TMM 10; TMM 10i; TMM 13i |

| Specialty & Legacy Series | Thermal-led or legacy programs needing specific mechanical or heritage specs. | TC350; TC600; AD250; AD300; AD350; AD1000; CLTE-MW; CLTE-P; CLTE-AT; CuClad; IsoClad |

Key Material Properties (Engineering Reference)

Selecting the right material is critical. Below are typical values for the most frequently requested materials in our factory.

| Material Model | Dielectric Constant (Dk) @ 10 GHz | Dissipation Factor (Df) | Thermal Conductivity (W/m/K) |

|---|---|---|---|

| RO4350B | 3.48 ±0.05 | 0.0037 | 0.62 |

| RO4003C | 3.38 ±0.05 | 0.0027 | 0.71 |

| RO4835 | 3.48 ± 0.05 | 0.0037 | 0.66 |

| RO3003 | 3.00 ± 0.04 | 0.0010 | 0.50 |

| RO3006 | 6.15 ± 0.15 | 0.0020 | 0.79 |

| RT/duroid 5880 | 2.20 ± 0.02 | 0.0009 | 0.20 |

| RT/duroid 6002 | 2.94 ± 0.04 | 0.0012 | 0.60 |

| TC350 | 3.50 ± 0.05 | 0.0020 | 1.0 |

Note: Values are for reference only. For precise Impedance Control calculations, please consult the official Rogers datasheet or our CAM engineers.

Rogers-Focused Fabrication Capabilities

- 1) PTFE Plasma Treatment (Desmear): Materials like RO3000 and RT/duroid are chemically inert. Standard chemical desmear fails to work on them. We utilize plasma etching to activate the hole walls before copper plating, ensuring reliable connectivity and preventing barrel cracks.

- 2) Hybrid Stack-Ups (Cost Optimization): We are experts in Hybrid PCBs. We can combine RF layers (Rogers cores) with non-RF layers (spread glass FR-4) for mechanical structure and power distribution. Benefit: significant cost reduction while maintaining RF performance.

- 3) Controlled Impedance & RF Finishes: Precision etching maintains trace width tolerance within ±0.5mil to ensure 50Ω/100Ω impedance. We recommend Immersion Silver or ENIG for the best RF conductivity and flatness.

- 4) Material Storage: Rogers materials are sensitive to moisture. We store all laminates in humidity-controlled environments and follow strict baking cycles before lamination to prevent delamination.

Start Your Rogers PCB Project

Upload Gerber Files for Quote

Please specify: Material Model (e.g., RO4350B), Thickness, and Copper Weight.

Frequently Asked Questions

Do you have specific Rogers materials in stock (e.g., RO4350B 20mil)?

We maintain a strategic stock of popular models like RO4350B, RO4003C, and RO3003 in common thicknesses. For less common models (certain RT/duroid or TMM series), we have a rapid procurement channel with Rogers distributors. Please specify the Model + Thickness in your quote request.

Is Rogers PCB much more expensive than FR-4?

Yes, the raw material cost is higher. However, we can optimize costs. RO4000 Series is moderately priced, similar processing to FR-4. PTFE (RO3000/RT/duroid) has higher cost due to material price and complex processing (plasma). Tip: ask our engineers about a Hybrid Stack-up (Rogers + FR4) to lower the total board cost.

Can you manufacture multilayer Rogers PCBs?

Absolutely. We regularly produce 4–12 layer RO4000 series boards (using RO4450 prepreg), multilayer radar boards using RO3000 series, and high-layer-count hybrid boards. The stack-up design is critical. Our engineering team can help you select the correct bonding materials.

Can you help me choose the right material?

If you provide your requirements (operating frequency, power level, size constraints, and application), we can recommend suitable Rogers materials. However, final verification usually requires your RF simulation.

Lock a Rogers RF stack?

Share RO4000/RO3000/RT/duroid layer counts, frequency targets, and hybrid FR-4 needs—we'll return bondply choices, plasma settings, and a build quote within one business day.