Industrial / Mobile / Service

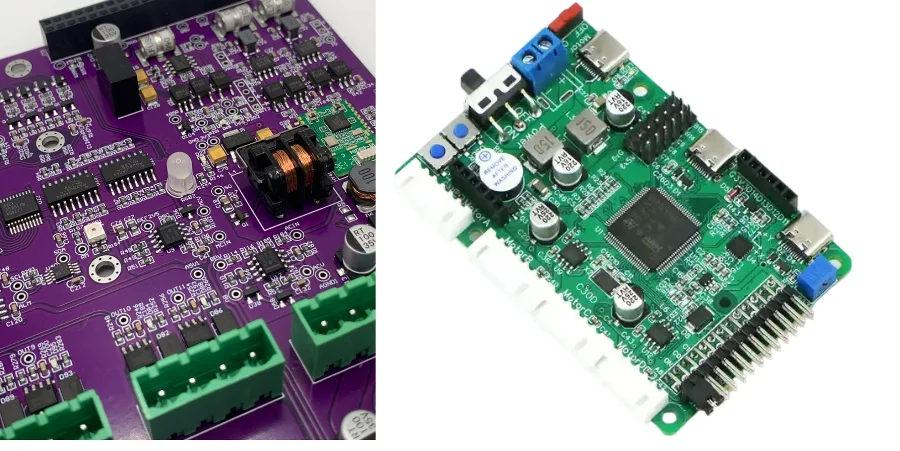

Robot PCB Manufacturing & PCB Assembly

Modern robots are complex electronic systems on wheels, tracks, rails, and arms. From industrial robots and cobots to AGVs/AMRs, warehouse robots, service robots, medical robots and inspection platforms, every function depends on Robot PCBs and Robot PCB assemblies.

Get an Instant Quote

Robot PCB Applications Overview

Key Robot PCB Application Areas

- Robot Controllers & Main Boards: Central control PCBs, CPU/SoC boards, motion controllers and I/O controllers.

- Servo Drive & Motor Control: Servo amplifier PCBs, BLDC driver boards, stepper drivers, joint motor control PCBAs.

- Sensors & Perception Modules: IMU/odometry boards, encoder/feedback PCBs, LiDAR/radar interface boards, 3D camera and vision system PCBAs.

- Communication & Networking: Fieldbus/Ethernet PCBs, wireless communication modules, robot gateway and cloud-connect PCBs.

- HMI, Teach Pendant & Operator Panels: Handheld teach pendant PCBAs, robot panel PCBs, indicator/display boards.

- Safety & IO Expansion: Safety IO module PCBs, emergency-stop and safety relay PCBAs, general IO and expansion cards.

- Power, Battery & Charging Systems: Battery management PCBs, DC/DC converter boards, robot power distribution PCBs, dock/charger PCBAs.

Reliable Operation in Dynamic Robotic Environments

Robot Controller & Main Control PCB & PCBA Solutions

- Real-Time Control & Processing: Multilayer Robot PCBs integrating MCUs/SoCs, FPGAs, memory and peripheral ICs for motion control, kinematics and safety logic.

- Multi-Bus Communication Support: Integration of industrial Ethernet, CAN/CANopen, EtherCAT, PROFINET, Modbus, serial links and proprietary buses on robot controller boards.

- Robust I/O & Interface Design: Digital and analog IO, encoder interfaces, safety signals and user I/O with appropriate isolation and protection on Robot controller PCBAs.

- Backplane & Modular Designs: Boards designed as main controllers with plug-in motion or IO modules, or as backplanes for modular robot control architectures.

Servo Drive, Motor Control & Power Stage PCBs

- High-Current, High-Voltage Design: Robot power PCBs with appropriate copper weights, creepage/clearance, slots and thermal management for servo and traction drives.

- Power Stage Integration: PCB layouts integrating MOSFETs/IGBTs, gate drivers, current sensors, shunts, snubbers and protection circuits in compact servo and drive modules.

- Feedback & Control Integration: On-board interfaces for encoder, resolver or Hall sensors, plus current and voltage sensing for closed-loop control.

- EMI/EMC-Aware Layout: Routing, grounding and filtering practices to limit EMC issues from high-frequency switching in robot cabinets and mobile platforms.

Sensor, Perception & Feedback PCBs for Robotics

- Low-Noise Sensor Front-Ends: PCBs for IMUs, encoders, force/torque and other sensors with careful analog layout and grounding to maintain signal quality.

- High-Speed Vision & LiDAR Interfaces: Boards handling MIPI/CSI, USB, Ethernet or custom interfaces to cameras and LiDAR, integrated into Robot PCBs or modules.

- Sensor Fusion & Pre-Processing Boards: PCBAs combining multiple sensors, pre-processing data near the sensors to reduce communication load and improve real-time behavior.

- Environmental & Mechanical Considerations: Sensor board designs that fit into robot arms, end-effectors, mobile bases and protective housings, with attention to vibration and cable routing.

Communication, Fieldbus & Networking PCBs for Robots

- Industrial Communication Interfaces: PCBs supporting CAN, CANopen, EtherCAT, PROFINET, Modbus, Ethernet/IP and other fieldbuses used in robotics and automation.

- Wireless Connectivity: Boards integrating Wi-Fi, Bluetooth, cellular or proprietary RF modules for mobile robot fleets and cloud connections.

- Gateway & Edge Controller PCBAs: Robotics PCBs that act as gateways between robot networks and plant or cloud systems, handling protocol conversion and data aggregation.

- Isolation & Protection: Transformer isolation, surge protection and filtering on communication ports for reliable operation in noisy industrial environments.

HMI, Teach Pendant & Robot Panel PCBs

- Display & Input Integration: PCBs for LCD/TFT displays, touchscreens, keypads, joysticks, emergency stop buttons and function keys.

- Industrial-Grade Construction: Robot PCBAs designed for frequent handling, shock, vibration and exposure to oils or dust in industrial environments.

- Communication & Power Interfaces: Boards connecting teach pendants to robot controllers via cables or wireless links, including power and safety circuits.

- User Feedback & Indicators: Integration of LEDs, buzzers and haptic feedback where required for intuitive operation.

Safety, IO & Expansion Module PCBs for Robots

- Emergency Stop & Safety Circuits: PCBs for E-stop circuits, safety relays and safety interlocks designed according to your functional safety architecture.

- Standard IO Modules: Digital and analog IO modules for interfacing with external sensors, actuators, fixtures and tooling around the robot.

- Tool & End-Effector Interface Boards: Robot PCBs mounted on end-effectors, supporting grippers, welding guns, screwdrivers, suction tools and other tooling.

- Isolation, Protection & Diagnostics: Optocouplers, surge protection, status LEDs and diagnostic circuits to simplify fault-finding and improve robustness.

Battery, Power Management & Charging PCBs for Mobile Robots

- Battery Management Systems: BMS PCBs for Li-ion/LiFePO4 packs, providing cell monitoring, balancing and protection functions.

- DC/DC & Power Distribution: Robot power PCBs converting and distributing voltage rails to controllers, drives, sensors, HMIs and communication modules.

- Charging & Docking Stations: PCBAs for plug-in and automated docking chargers used in AGV/AMR fleets and service robots.

- Protection & Safety: Over-current, over/under-voltage, short-circuit and thermal protections integrated into power and battery boards.

Testing & Quality Control for Robot PCBAs

- SPI (Solder Paste Inspection): Ensures correct solder paste volume and alignment, reducing soldering defects on fine-pitch MCUs, FPGAs and connectors.

- AOI (Automated Optical Inspection): Checks component presence, type, polarity, placement and visible solder joints after reflow.

- X-Ray Inspection (As Needed): Evaluates hidden solder joints under BGA, LGA, QFN and power packages commonly used on robot controllers and drive boards.

- In-Circuit Test (ICT) / Flying Probe (When Designed In): Verifies electrical connectivity and component values where test points and fixtures are available.

- Functional Test (FCT): Runs power-up and robot-specific tests, such as communication checks, sensor readouts, motor drive tests or IO scans, according to your test specifications.

- Final Quality Inspection & Traceability: Confirms labeling, revision, cosmetic quality and packing, with lot-level or board-level traceability to support field maintenance and fleet-level quality tracking.

From Prototype to Fleet Deployment: Partnering with APTPCB for Robot PCB Projects

- One-Stop PCB + PCBA: PCB fabrication and assembly in one factory reduces handoff issues, accelerates design iterations and simplifies your supply chain.

- Flexible Volumes: Support for prototypes, pilot runs and full production as your robot platform scales from demo to series product and fleets.

- Engineering Collaboration: Direct communication on stackup, materials, DFM, DFT and test strategy tailored to robotics and automation needs.

- Stable, Repeatable Quality: Process control, testing and documentation designed to deliver repeatable builds, critical for robots deployed across many sites or customers.

Frequently Asked Questions

Which robot applications do you cover?

Industrial robots, cobots, SCARA, welding/painting robots, AGVs/AMRs, warehouse robots, service robots, medical and inspection robots, plus controllers, chargers and base stations.

What PCB/PCBA types do you build for robotics?

Robot controllers and main boards, servo drive and motor control PCBAs, sensor/perception boards, communication/network modules, HMI/teach pendant panels, safety/IO modules, and power/battery/charging PCBAs.

How do you ensure reliability in robotic environments?

Robust stackups and copper weights, creepage/clearance, EMI/EMC-aware layouts, vibration-tolerant assembly, and layered inspection (SPI, AOI, X-ray, ICT/FCT) with traceability.

Can you support industrial communication and wireless?

Yes - EtherCAT, PROFINET, CAN/CANopen, Modbus, Ethernet/IP, plus Wi-Fi/Bluetooth/cellular RF modules and gateway PCBAs with isolation and protection.

Do you handle quick ramps from prototype to fleets?

Yes - one-stop PCB + PCBA with flexible volumes, fast DFM, and synchronized builds to support prototypes, pilots and fleet deployments.

Request Robot PCB & PCBA Manufacturing Support

Share your robot controller, drive, sensor, communication, HMI, safety IO and power requirements - we will deliver a production-ready PCB/PCBA plan with testing and traceability.