Differential Skew Mitigation

Uniformized glass removes large resin windows, keeping skew ≤5 mil across 10 in routes and easing COM budgets.

- Less phase conversion to common mode

- Allows longer straight routing

- Reduces need for serpentine compensation

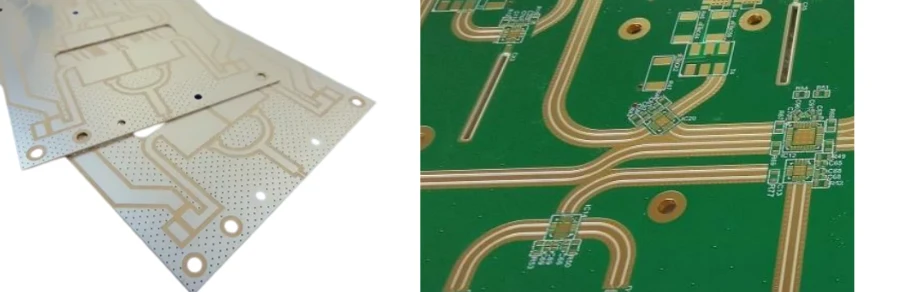

Materials

Spread-glass fabrics (1035, 1067, 2116, 3313, UTS) paired with VLP copper cut weave-induced skew and insertion loss enough to keep 10–28 Gbps channels in spec. We package the routing tactics, documentation prompts, and correlation workflow we use on RayPCB backplanes so SI teams can rely on the data.

Uniformized glass removes large resin windows, keeping skew ≤5 mil across 10 in routes and easing COM budgets.

Spread weaves hold Dk constant so solver results track TDR coupons within ±5% without over-guardbanding.

Spread fabrics plus VLP copper reduce high-frequency loss 3–5%, buying extra reach on 10–28 G lanes.

| Style | Construction | Use Case |

|---|---|---|

| 1035 / 1067 | Spread 1 oz warp/weft | Outer signal layers and stripline pairs |

| 2116 / 3313 | Dual-ply spread | Core layers balancing stiffness & skew |

| Spread 7628 | Macro spread heavy weave | Backplane cores needing rigidity |

| Ultra-Thin Spread (UTS) | Custom microspread | Premium skew-critical lanes |

| Spread Hybrid Stack | Mix of spread and standard | Cost-optimized builds |

| Material Set | Dielectric Constant | Dissipation Factor | Notes |

|---|---|---|---|

| FR408HR + 1035 spread | 3.66 | 0.009 | Skew ≤5 mil with VLP copper |

| Megtron 6 + 1067 spread | 3.40 | 0.0020 | Used on 56 G lanes |

| Low-loss FR-4 + 2116 spread | 3.55 | 0.004 | Mid-loss builds |

| EM-826 + 3313 spread | 3.48 | 0.003 | Long reach 28 Gbps |

| Hybrid (spread outer / std inner) | Layer-dependent | - | Cost-optimized approach |

Values depend on resin and copper selection; reference laminate datasheets and lot certs for final solver inputs.

Spread 1035 outers and 2116 cores supporting PCIe Gen4/5 lanes.

Spread 3313 core pairs for long differential runs, standard glass for planes.

Spread-glass FR-4 digital sections tied to PTFE RF layers.

Traveler lists style, supplier, and acceptable alternates per dielectric.

We publish recommended routing angles or zig-zag patterns when spread is unavailable on specific layers.

Pair spread fabrics with VLP/HVLP copper and log Ra/Rz + micro-etch depth.

TDR/VNA coupons placed on the same fabric orientation as product traces.

Spread-glass FR-4 reduces skew on 16–32 GT/s differential pairs.

18–30 layer backplanes with spread cores for 25–56 G lanes.

Hybrid FR-4 + RF designs where spread glass keeps digital skew in check.

Inputs needed before we lock spread-glass choices.

Define allowable skew per channel to decide if full spread or mixed weave is required.

Choose resin system (FR408HR, Megtron, low-loss FR-4) and spread style per layer.

Plan coupon placement, TDR/VNA scope, and solver correlation artifacts.

Yes, when specified in the stack table. We lock glass styles per layer and document approved alternates to avoid substitutions.

Cost impact is modest (≈3–5% per layer). We stock common spread styles and can pull specialty rolls within 1–2 weeks.

We route skew test coupons alongside product nets, measure skew with TDR/VNA, and share overlays with solver predictions.

Send stackup layers, lane lengths, and skew budget—we'll recommend glass styles, routing angles, and a build quote within one business day.