Turnkey PCBA

We source + assemble + test

APTPCB is an electronics manufacturer offering end-to-end PCB assembly (PCBA) services—from component sourcing and kitting to SMT & through-hole assembly, inspection, testing, and final box build. Whether you're launching a new design or scaling a proven product, we help you build with predictable quality, clear documentation, and responsive engineering support.

We source + assemble + test

You supply key parts, we source the rest

You supply all parts, we assemble

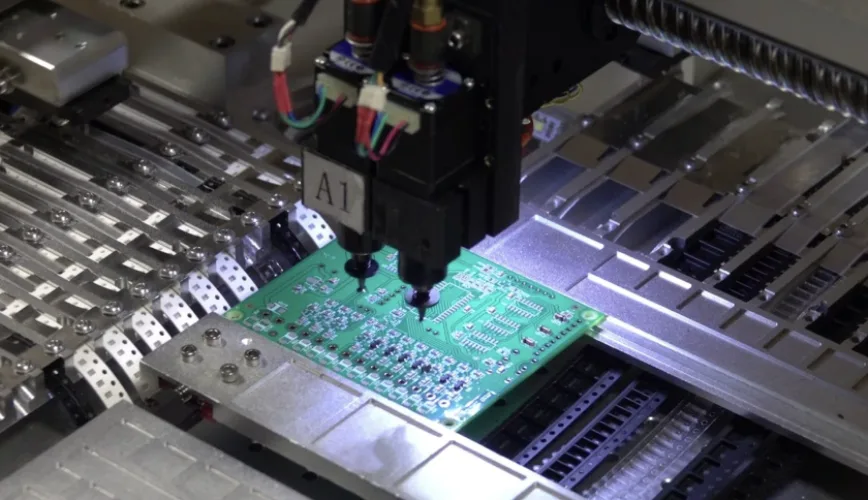

State-of-the-art equipment and processes designed for high-volume production with precision quality.

APTPCB supports a wide range of PCBA types. If your project has special requirements, share them early—our assembly plan and quote will align to your acceptance criteria.

Surface mount and through-hole components in a single build with optimized workflow sequencing.

BGA, QFN, QFP, CSP placement with appropriate inspection methods and controlled rework.

Process adapted to specialized materials and design requirements for RF applications.

Heavy connectors, thermal considerations, and high-current path requirements handled properly.

Cable assembly, wire harness, and mechanical integration for complete box build solutions.

Specialized handling for polyimide substrates with controlled reflow profiles.

Our assembly process is designed for repeatability across prototypes and production with full process controls.

High-speed placement with repeatability across prototypes and production

Critical for connectors, mechanical strength, and power components

Process discipline and inspection strategy for advanced packages

These services are frequently bundled into turnkey PCBA programs.

A structured process from file intake to shipping keeps quality, timeline, and documentation predictable.

We review BOM integrity, assembly drawing notes, test requirements, target quantities, and lead time for completeness.

We flag polarity ambiguities, fine-pitch constraints, stencil aperture risks, and supply-chain issues before building.

Component availability confirmation, substitution approvals, kitting status, and ETA alignment with your schedule.

SMT printing → placement → reflow; THT insertion → soldering → inspection, with controlled rework as required.

AOI/X-ray/visual inspection per plan, plus ICT/FCT or custom verification per your acceptance criteria.

ESD-safe packaging, labeling/serialization if required, and shipping aligned to your destination and timeline.

Provide these files to get a fast, accurate quote—send what you have, we'll tell you what's needed.

Use these to reduce iteration time and improve first-pass assembly success.

Provide clear polarity marks for diodes, electrolytics, and IC pin-1 orientation

Keep test points accessible if ICT or production debug is required

Avoid placing tall parts that block AOI view of critical solder joints

Define keepout areas for tooling, depanelization, and coating zones

Confirm package and footprint match in BOM to prevent sourcing mistakes

Document special soldering requirements for thermal mass areas and heavy copper

APTPCB PCBA services are frequently used by teams building products in these sectors.

Browse PCBA services and resources by category to compare processes, quality checkpoints, and production options.

Clarity on turnkey models, NPI support, test coverage, and compliance.

Send your BOM and assembly files—we'll reply with a build plan and quote aligned to your schedule, quality requirements, and documentation needs.