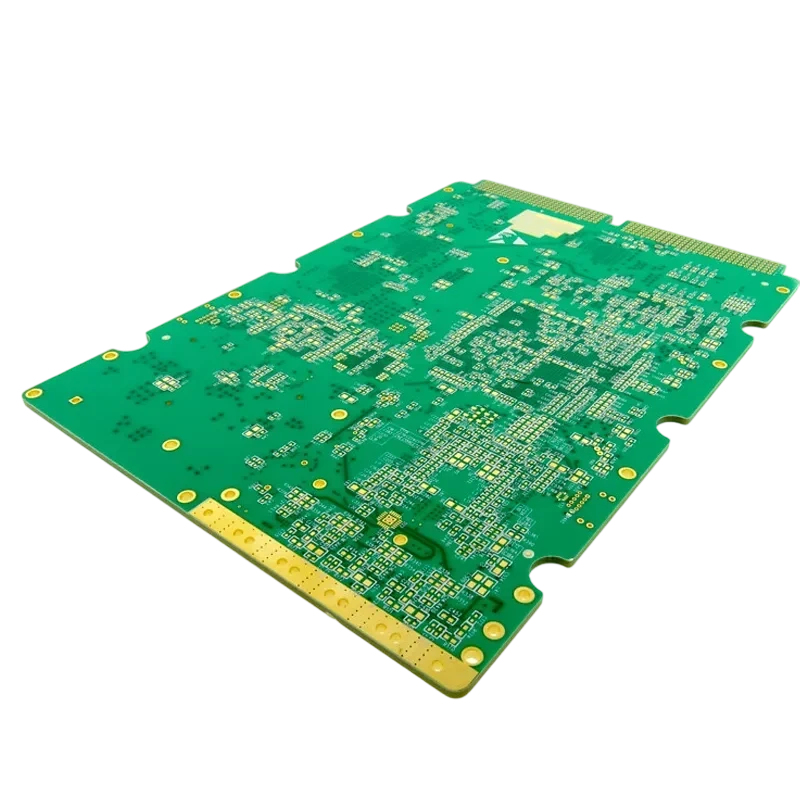

FR4 / HDI / Flex / Rigid-Flex / Ceramic / Metal Core

Quick Turn PCB Services Covering Every Board Type You Need

Quickly produce and assemble FR4, HDI, flex, rigid-flex, ceramic, aluminum/MCPCB, RF, high-speed, and heavy-copper PCBs under one workflow-fewer suppliers to manage, faster ECO cycles, and synchronized delivery ready for assembly and test.

Get an Instant Quote

Quick Turn PCB Services Covering Nearly Every Board Type You Need

Quick Turn PCB Manufacturing Capabilities: From FR4 and HDI to Flex, Ceramic and Metal Core

- Standard FR4 quick turn PCBs - Single-sided, double-sided, and multilayer PCBs for general-purpose electronics.

- Multilayer quick turn PCBs - 4-32+ layers with controlled impedance, buried and blind vias, and high-density routing.

- HDI PCB quick turn production - 1+N+1, 2+N+2 and higher-order HDI structures, with microvias, via-in-pad, copper-filled vias, and ultra-fine line widths for high I/O-count devices.

- Quick turn flex PCBs (FPCs) - Thin, bendable circuits for cameras, wearables, connectors, and dynamic applications.

- Quick turn rigid-flex PCBs - Hybrid structures combining rigid sections for components and flexible sections for interconnects, ideal for compact 3D assemblies.

- Quick turn ceramic PCBs - Alumina (Al₂O₃) and aluminum nitride (AlN) for high-temperature, high-power, and high-frequency designs.

- Quick turn aluminum PCBs and MCPCBs - Metal core PCBs for LED lighting, power conversion, and automotive electronics where efficient heat dissipation is critical.

- High-frequency and RF quick turn PCBs - Boards on PTFE and other low-loss materials for 5G, radar, RF modules, and wireless communication.

- High-speed digital quick turn PCBs - Optimized stack-ups and routing for multi-gigabit interfaces, high-speed backplanes, and advanced computing systems.

- Heavy copper and high-current quick turn PCBs - Thick copper and special stack-ups for power electronics, motor drives, and industrial control.

- Layer counts from 1 to 32+ layers (depending on PCB type)

- Minimum trace/space down to 3/3 mil (replace with your actual capability)

- Minimum finished hole size down to 0.1 mm / 4 mil

- Board thickness from 0.2 mm to 8 mm

- Copper weight from 0.5 oz to 20 oz on inner and outer layers

- Surface finishes including ENIG, lead-free HASL, immersion silver, immersion tin, and OSP with multiple solder mask colors

From Rapid Prototyping to Pilot and Low-Volume Production in Quick Turn Mode

- Concept proof and engineering prototypes: Very small quantities (e.g., 5-20 pieces) for design validation, signal integrity checks, and initial functional tests.

- Design verification and pre-production: Medium quantities to verify manufacturability, test coverage, and reliability before committing to large-scale production.

- Pilot production and low-volume quick turn PCB manufacturing: Dozens to hundreds or a few thousand boards for early customer shipments, field tests, or niche products.

- 24-48 hours for simple FR4 prototypes (depending on your actual capability)

- About 3-7 working days for complex multilayer, HDI, flex, rigid-flex, ceramic, or metal core boards, subject to design complexity and order quantity

Integrated Quick Turn PCB Assembly: From Bare Board to Fully Assembled PCBA

- SMT and THT assembly for FR4, multilayer, HDI, flex, rigid-flex, ceramic, and metal core PCBs.

- Fine-pitch and high-density assembly for BGAs, QFNs, CSPs, and 01005 components on HDI and high-speed boards.

- Quick turn ceramic PCB assembly for power modules, RF amplifiers, and high-temperature applications.

- Quick turn flex and rigid-flex PCB assembly with specialized fixturing and process control to protect fragile structures.

- Quick turn MCPCB and aluminum PCB assembly with optimized thermal profiles for high-power LEDs and power electronics.

- In a turnkey quick turn PCB assembly project, we source all components based on your BOM, manage lead times, and handle logistics.

- In a consigned or partial-turnkey model, you provide some or all of the key components, and we integrate them into the assembly flow.

Engineering Support, DFM/DFT, and Quality Control in Quick Turn PCB Projects

- Front-end engineering review (DFM/DFT): Analyze Gerbers/ODB++, stack-up data, and BOM to detect potential issues such as insufficient clearances, problematic via structures, solder mask slivers, thermal imbalances, or test access limitations.

- Stack-up and material recommendations: For HDI, high-frequency, high-speed digital, ceramic, and metal core quick turn PCBs, advise on layer structures, dielectric choices, and copper weights that balance performance, cost, and manufacturability.

- Impedance and signal integrity considerations: For RF and high-speed quick turn PCBs, ensure that line widths, spacing, and reference planes are compatible with the specified impedance and material properties.

- Process control and inspection: AOI for bare boards and assembled PCBs, electrical testing where required, X-ray inspection for BGA and LGA packages, and adherence to recognized IPC class and customer-specific requirements.

- Feedback loop for continuous improvement: Issues found during assembly or testing are fed back to design and process engineering, so subsequent quick turn PCB runs and future mass production benefit from proven design and process optimizations.

How Our Quick Turn PCB Service Fits into Your Long-Term Manufacturing Strategy

- Multiple PCB technologies under one roof, so your engineering team does not need to manage different vendors for FR4, HDI, ceramic, flex, RF, high-speed, and metal core boards.

- Consistent documentation and traceability, making it easier to maintain quality records, perform audits, and meet regulatory requirements in markets such as automotive, industrial, medical, and telecommunications.

- Flexible logistics and scheduling, with options for expedited shipping, split deliveries, and synchronized shipments of PCBs, components, and assembled boards.

Frequently Asked Questions

Answers to the questions we hear most from hardware teams.

Which PCB types can you quick turn?

Standard FR4, multilayer, HDI, flex, rigid-flex, ceramic, aluminum/MCPCB, RF/high-frequency, high-speed digital, and heavy-copper power boards can all run in our quick turn workflow.

What are typical quick turn lead times?

Simple FR4 prototypes can ship in 24-48 hours; complex multilayer, HDI, flex, rigid-flex, ceramic, or metal core boards typically take about 3-7 working days depending on design and quantity.

Do you also handle quick turn assembly?

Yes. We offer turnkey, consigned, or partial-turnkey assembly with SMT/THT, fine-pitch BGA/QFN/01005 capability, and AOI/X-ray plus optional ICT/functional testing.

How do you ensure manufacturability and quality under tight timelines?

Front-end DFM/DFT reviews, stack-up/material recommendations, impedance/signal-integrity checks, AOI/e-test, X-ray for BGAs, and feedback loops keep yields high even in quick turn.

Can quick turn support pilot or low-volume production?

Yes-beyond prototypes, we run pilot and low-volume builds with priority material allocation, fast-line slots, and synchronized fab plus assembly to support early shipments and field tests.

Request a Quick Turn PCB Quote

Share your Gerber/ODB++/IPC-2581 files and BOM-we will align stack-up, lead time, and synchronized fabrication plus assembly for your next quick turn build.