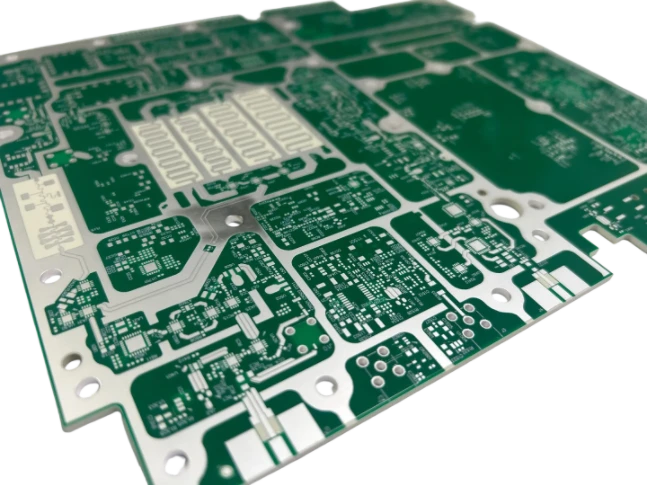

RF CAM & Stackup Engineering

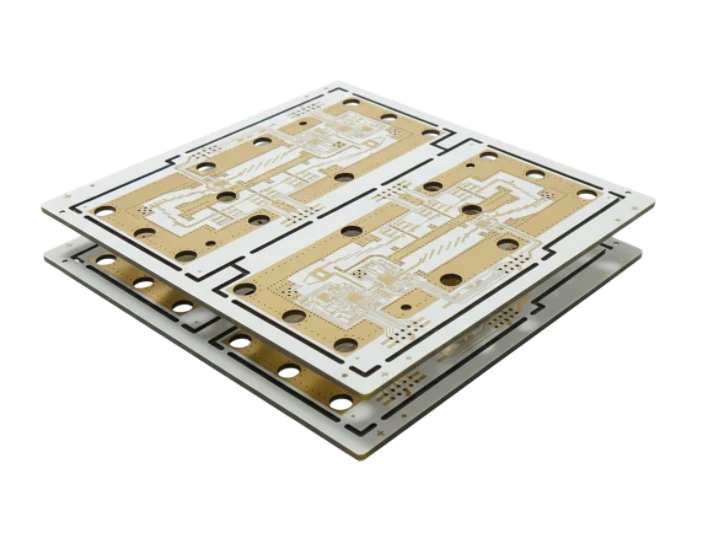

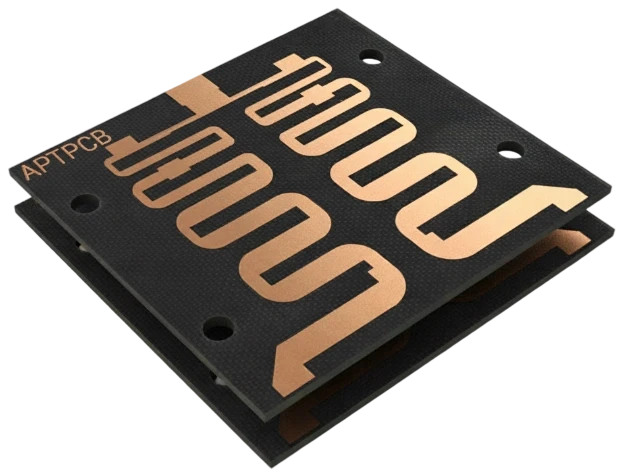

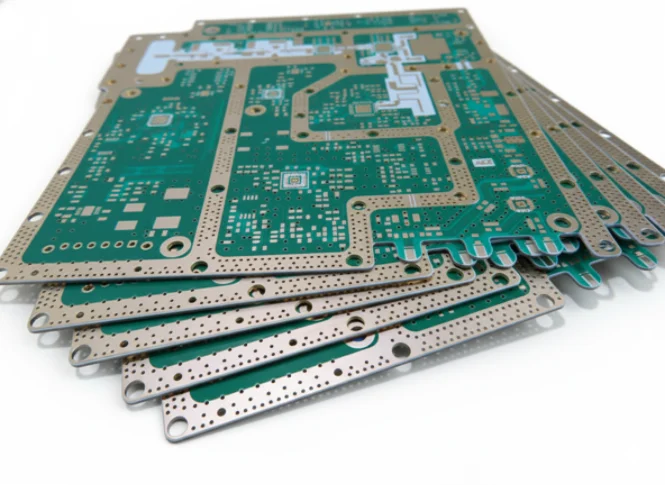

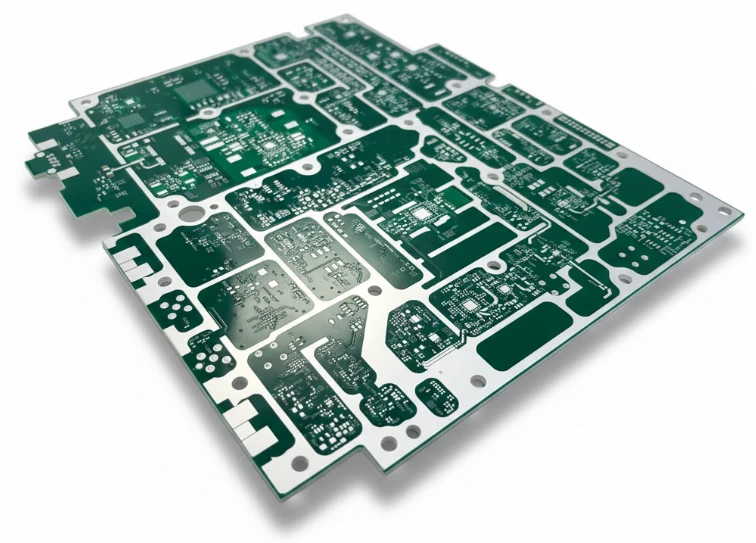

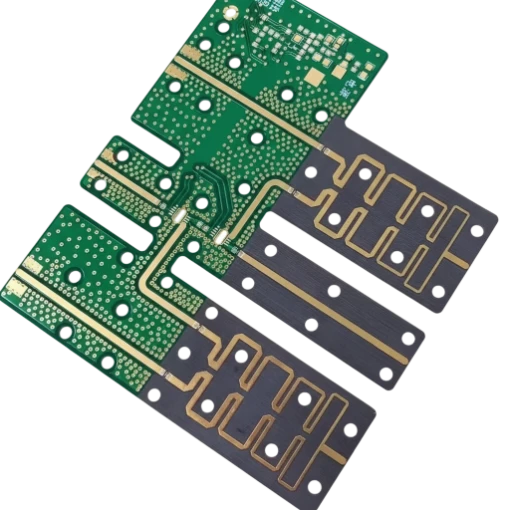

CAM teams convert Gerber/ODB++ into RF-ready tooling, defining dielectric targets, cavity paths, and impedance coupons.

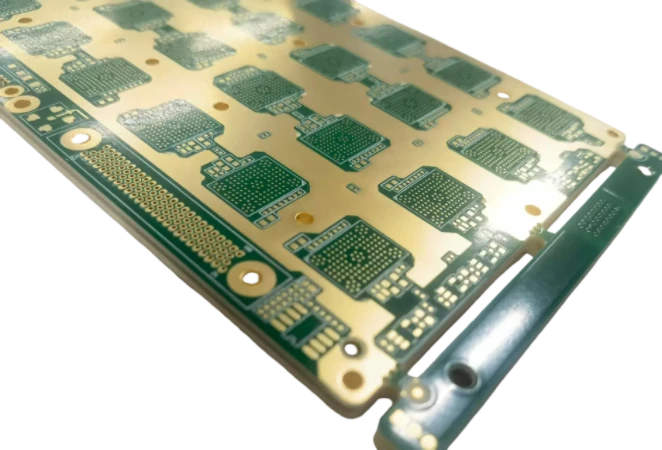

- Confirm dielectric constants, tolerance, and copper roughness for each layer.

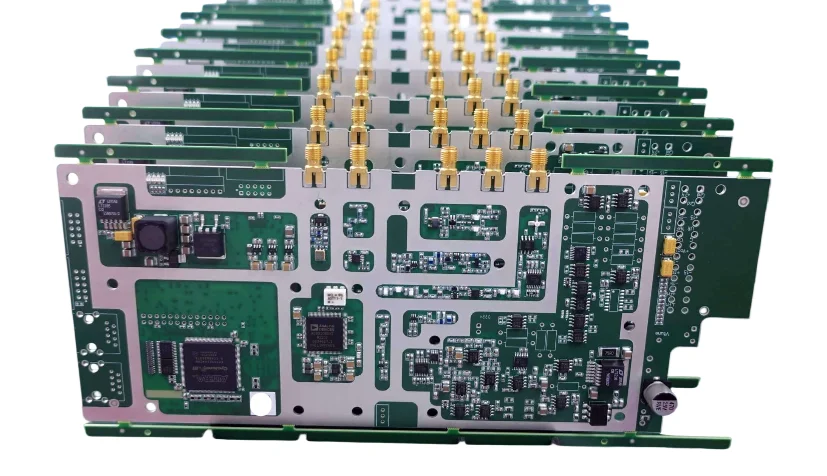

- Define impedance coupons and RF launch references.

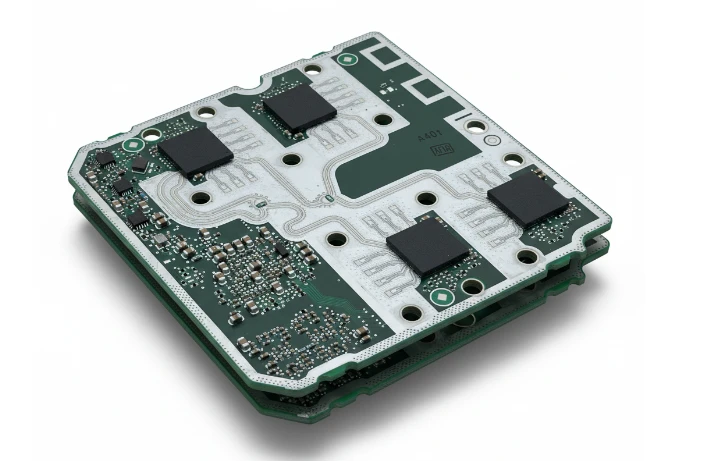

- Plan cavity depths, plated slots, and keep-outs around antennas.

- Schedule selective ENEPIG/soft gold for wire bond or probe pads.

- Specify RF via stitching density and backdrill requirements.

- Document handling/bake requirements for PTFE/ceramic materials.

- Release fabrication notes covering surface cleanliness and packaging.