Unified Manufacturing

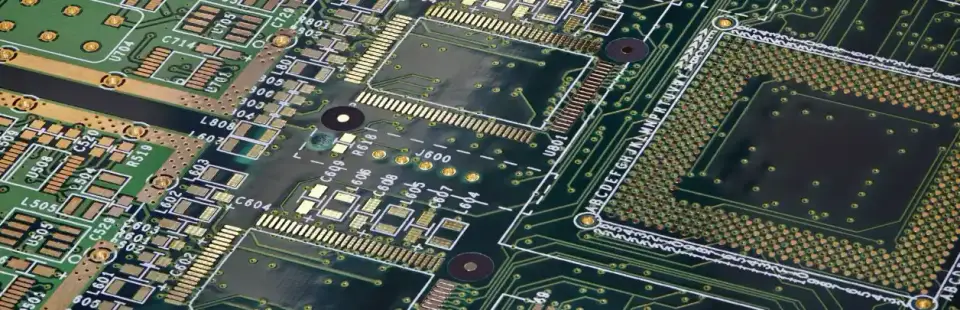

One Team Orchestrating High-Reliability PCB & PCBA Programs

APTPCB aligns multilayer PCB fabrication, turnkey assembly, and compliance support inside one manufacturing engine so engineering teams can launch faster with audit-ready evidence.

Get an Instant Quote

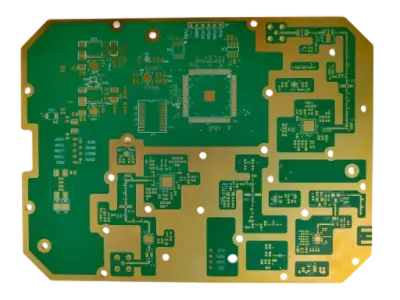

Precision Engineering

IPC Class 3 standards compliant. Advanced HDI and rigid-flex capabilities for mission-critical applications.

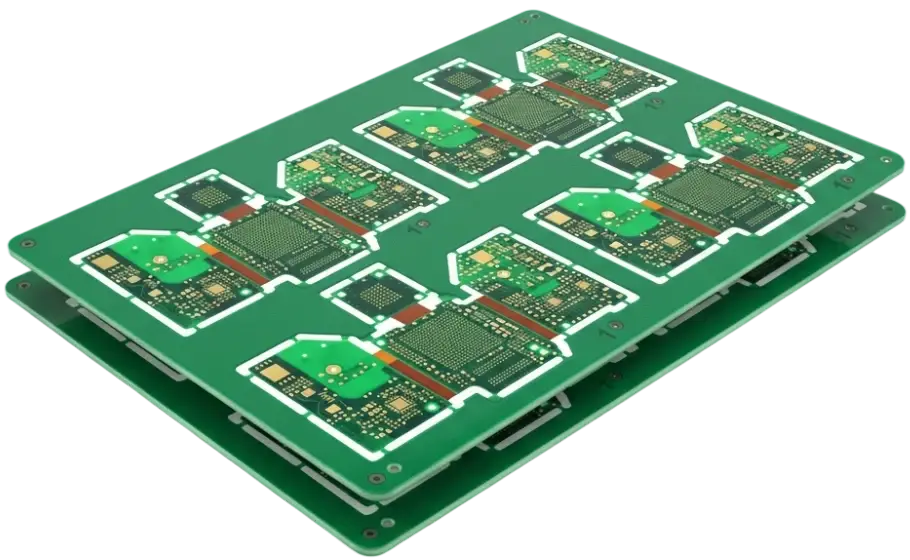

Rapid Scale-Up

Seamless transition from prototype to mass production. Automated assembly lines ensuring consistent quality.

Global Logistics

Optimized supply chain management. Worldwide shipping with real-time tracking and customs support.

Engineered for Complexity.

Our core competencies across PCB manufacturing, PCBA assembly, and quality assurance—designed to handle the most demanding specifications in the industry.

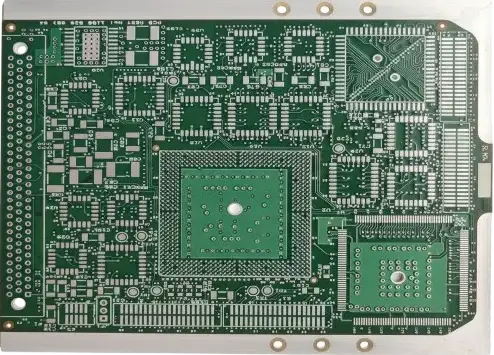

Advanced Fabrication Technology

High-End Product Types

Premium Materials

We partner with industry-leading material suppliers to ensure signal integrity and reliability.

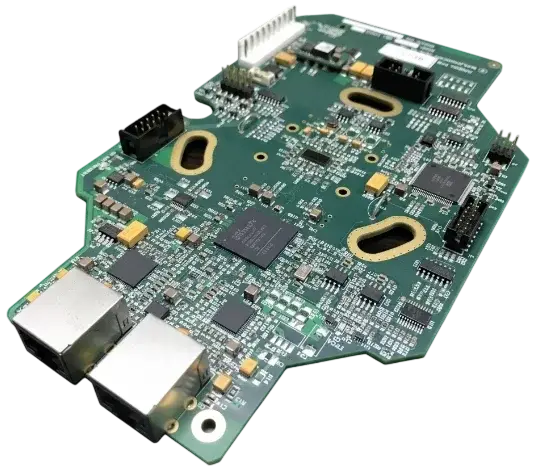

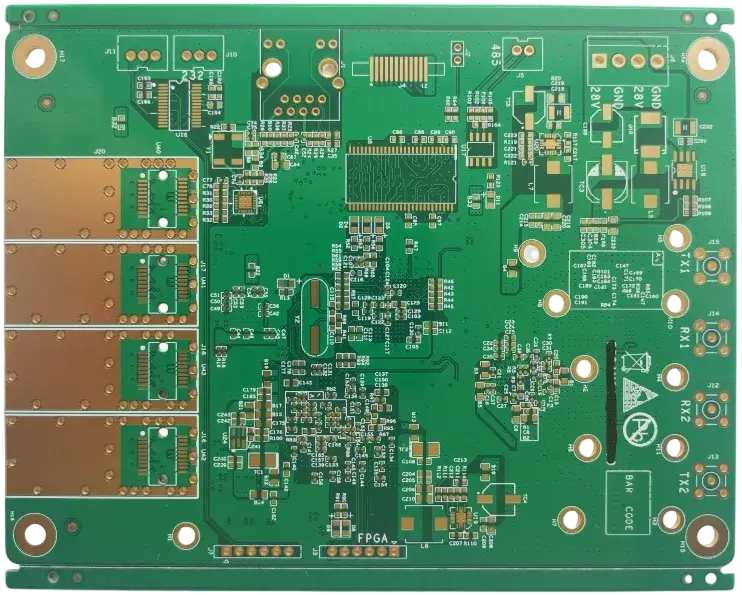

Seamless Turnkey Integration

PCB Design and Fabrication;Component Sourcing;PCB Assembly and Test

Testing & Quality

- • AOI & X-Ray Inspection

- • ICT (In-Circuit Test)

- • Functional Testing (FCT)

Engineering Capabilities

Pushing the boundaries of what's possible with cutting-edge manufacturing processes and materials.

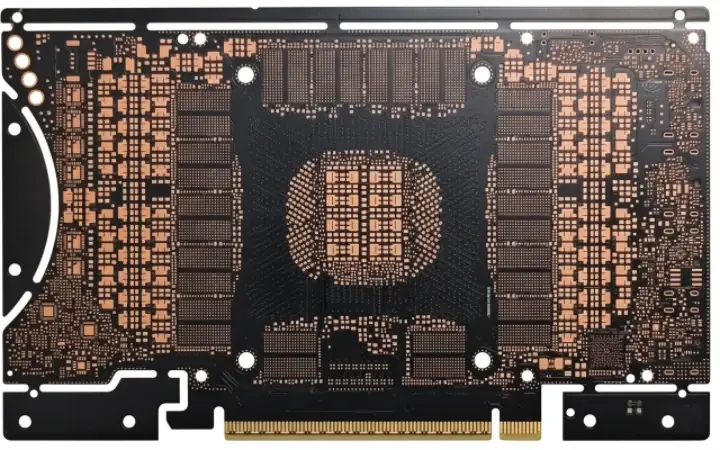

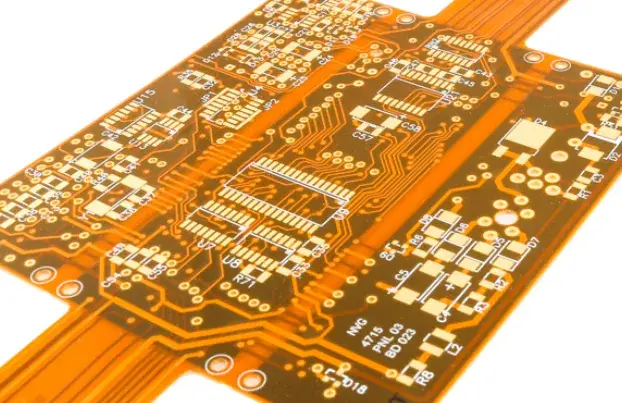

Rigid & Flex

- Up to 64 Layers (Rigid)

- Up to 12 Layers (Flex)

- Any-Layer HDI

- Staggered/Stacked Vias

Flex PCB

- Dynamic Flex Stackups

- Adhesiveless Copper

- Coverlay Registration ≤35µm

- Bend Qualification

Metal PCB

- Aluminum / Copper Core

- >12 W/m·K Thermal Path

- Heavy Copper (up to 12oz)

- Embedded Coin

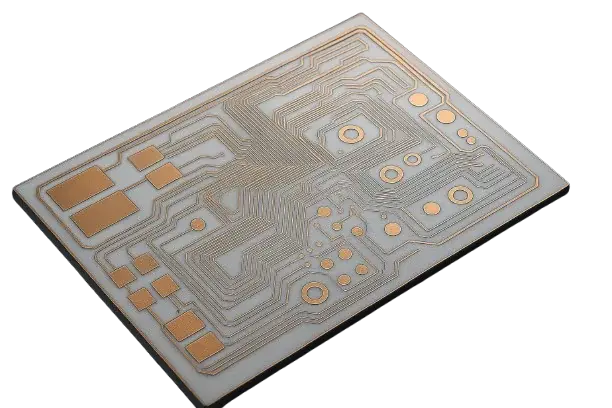

Ceramic PCB

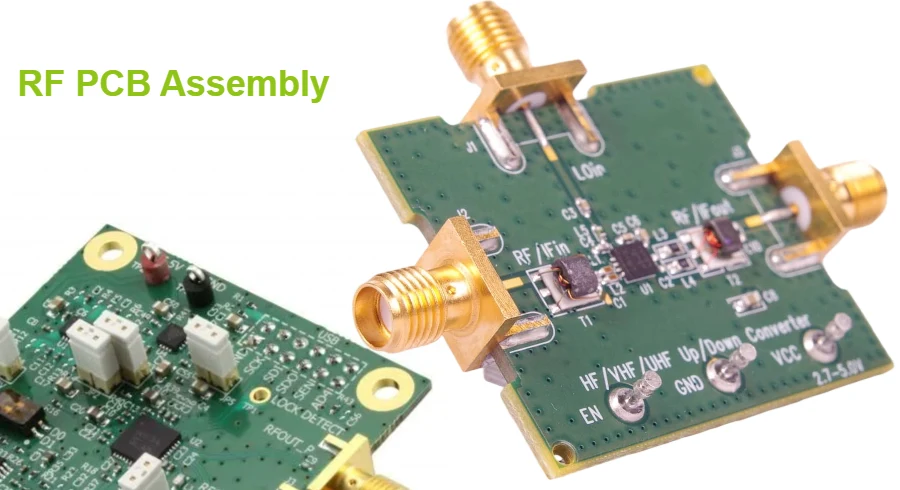

- Alumina & AlN Substrates

- High Thermal Conductivity

- RF/Microwave Applications

- Extreme Reliability

Solutions Tuned to High-Growth Electronics Segments

Each industry path packages stackups, validation evidence, and compliance workflows so hardware teams can qualify with confidence.

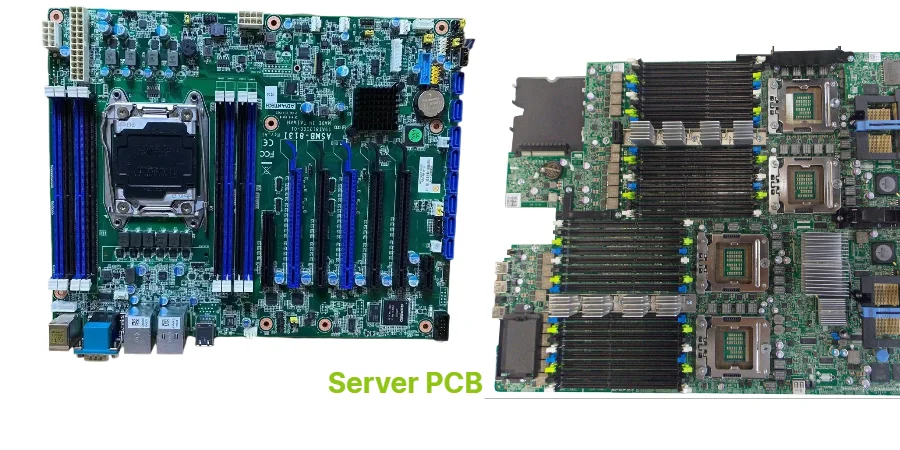

Server & Data Center

Backplanes, line cards, and accelerator modules with PAM4-ready channels.

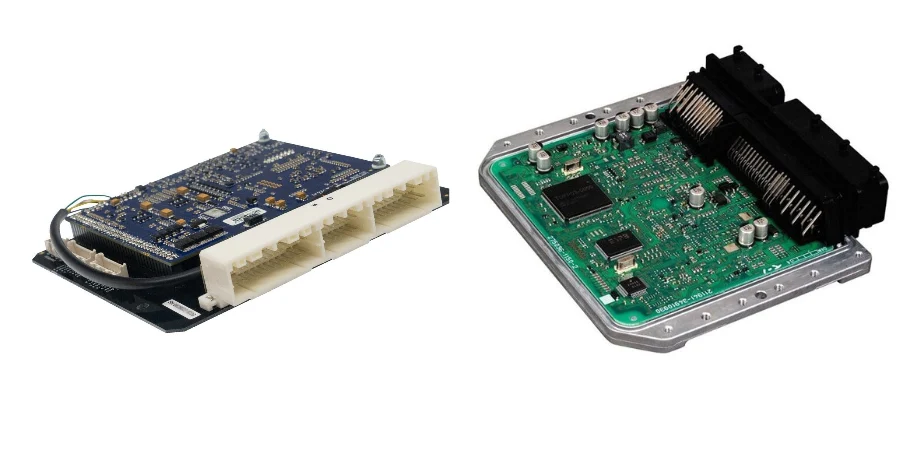

Automotive Electronics

ADAS controllers, BMS, and domain ECUs with IATF 16949 and PPAP coverage.

Medical Devices

Imaging, diagnostics, and wearable platforms ready for ISO 13485 alignment.

Communication Equipment

RF front ends, phased arrays, and satellite payloads with controlled impedance.

Aerospace & Defense

Mission-critical avionics, radar, and rugged electronics with traceable materials and environmental testing.

Industrial Control

PLCs, motion control, and IO modules built for 24/7 uptime in harsh environments.

Resources for Designers

Streamline your design-to-manufacturing workflow with our suite of free online tools, technical guides, and engineering resources.

Gerber Viewer

Instant online preview of your PCB files. Check layers, drills, and dimensions before fabrication.

Launch Tool →PCB Viewer

Interactive 3D visualization of PCB stackups and layer arrangements. Verify design before manufacturing.

View PCB →BOM Viewer

Analyze and validate your Bill of Materials. Check component availability and sourcing details.

View BOM →3D Viewer

Explore 3D models of your PCB and PCBA assemblies. Rotate, zoom, and inspect component placement.

View 3D →Circuit Simulator

Simulate circuit behavior and validate electrical performance before manufacturing.

Simulate →Impedance Calculator

Calculate trace width and spacing for controlled impedance stackups. Support for microstrip and stripline.

Calculate →Materials & Datasheets

Download material datasheets, design guidelines, and process capability notes for your projects.

Download →FAQ Hub

Find answers to common questions about PCB design, manufacturing, and assembly processes.

Browse FAQs →Engineering Blog

Read technical articles, case studies, and industry insights from our engineering team.

Read Blog →Ready to Scale?

Join the world's leading innovators who trust APTPCB with their most critical electronics.